XieXing

XieXing  2025-04-14

2025-04-14

What are the manufacturing processes of metal badge?

Want to finally get a fine, high-quality metal badges? you must first have a clear understanding of the process of custom metal badges. Let's go ahead and learn about it.

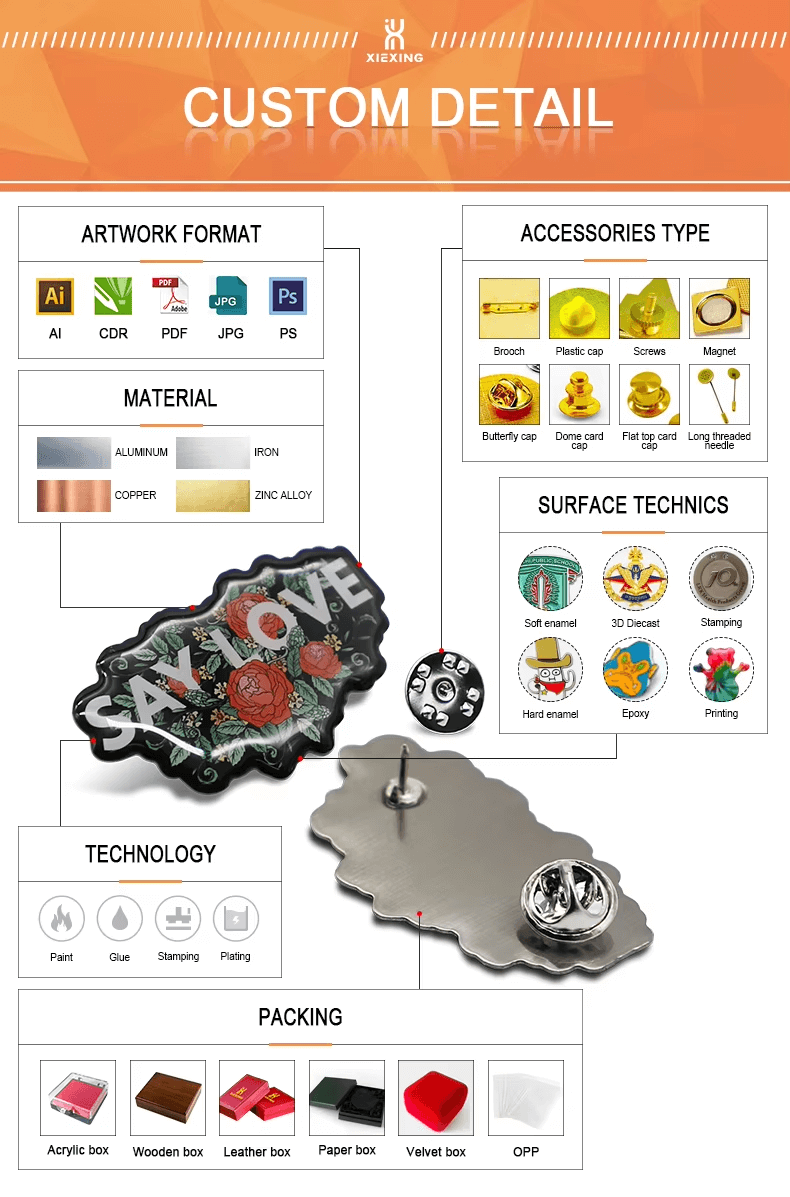

The raw materials of the metal card are mainly copper, iron, and zinc alloy. First of all, you need to draw a design artwork. If you need help, you can contact suppliers do you a favor. After check the all details, factory will start to engrave a mold for each design. Actually, we will make a sample first for customer to check the effects, and then mass production. Stamping, diveting pin, polishing, plated, painting, QC, and packeage. Normally, the surface of metal badges will be electroplated with gold or silver according to the requirement. It is widely used as brooch, hat pin, bag pin etc.

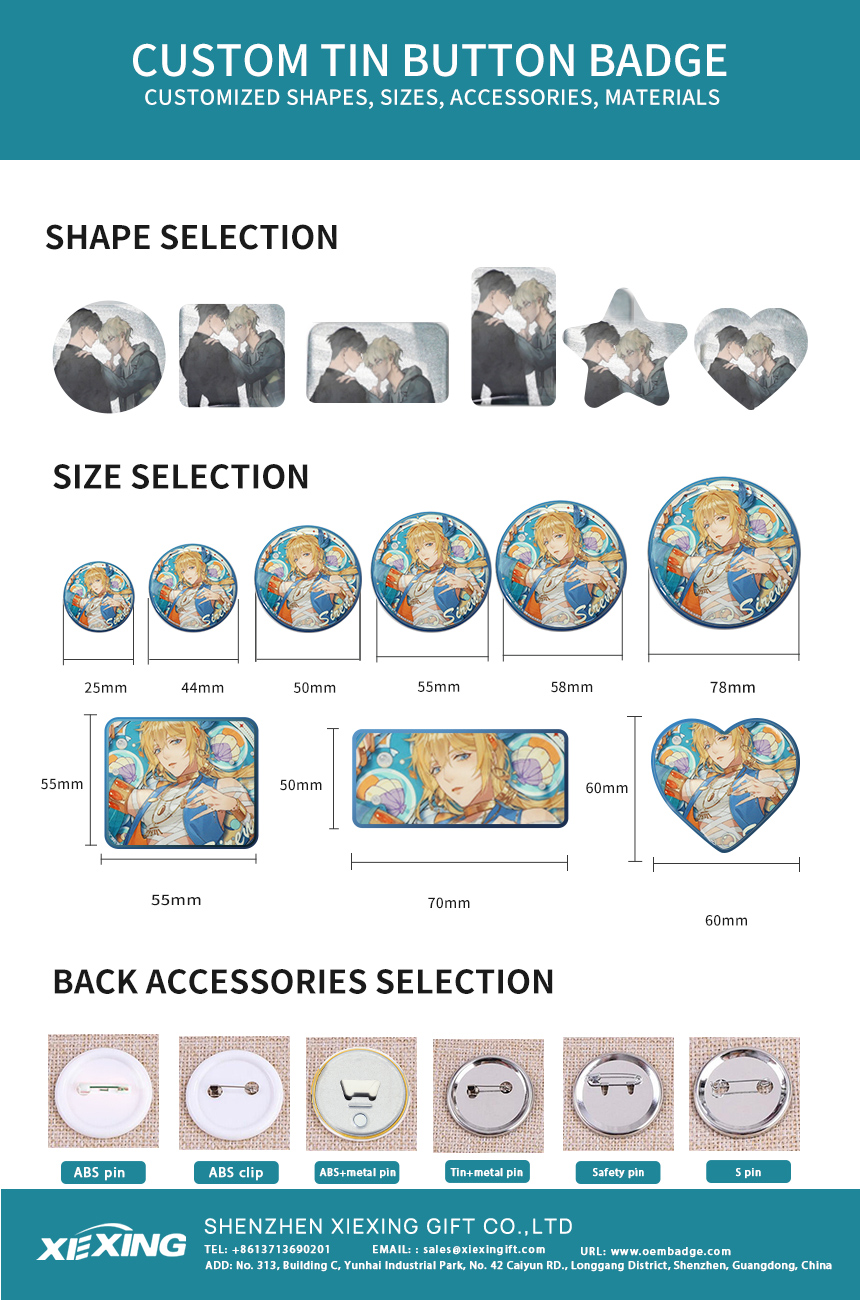

According to the technology, metal badge can be divided into soft enamel badge, hard enamel badge, print and epoxy badge, metal stamping badge, tin button badge and other series of metal badge.

It can be equipped with butterfly hats, safety pins, silicone caps, etc., and used as medals, armbands, hat badges and tie badges.

It can be put on and taken off at any time. You can also engrave your own logo on the back to make it unique.